Manufacturing Safety

Bringing Vision To Manufacturing Safety Blind Spots

Safety use cases continue to grow as manufacturing processes and equipment evolve.

High accuracy, high complexity, low latency, and ongoing safety regulation changes force manufacturers to add more robust edge/onsite computing capability to identify and prevent safety issues.

Let’s look at how ThinkIQ’s Discrete software works

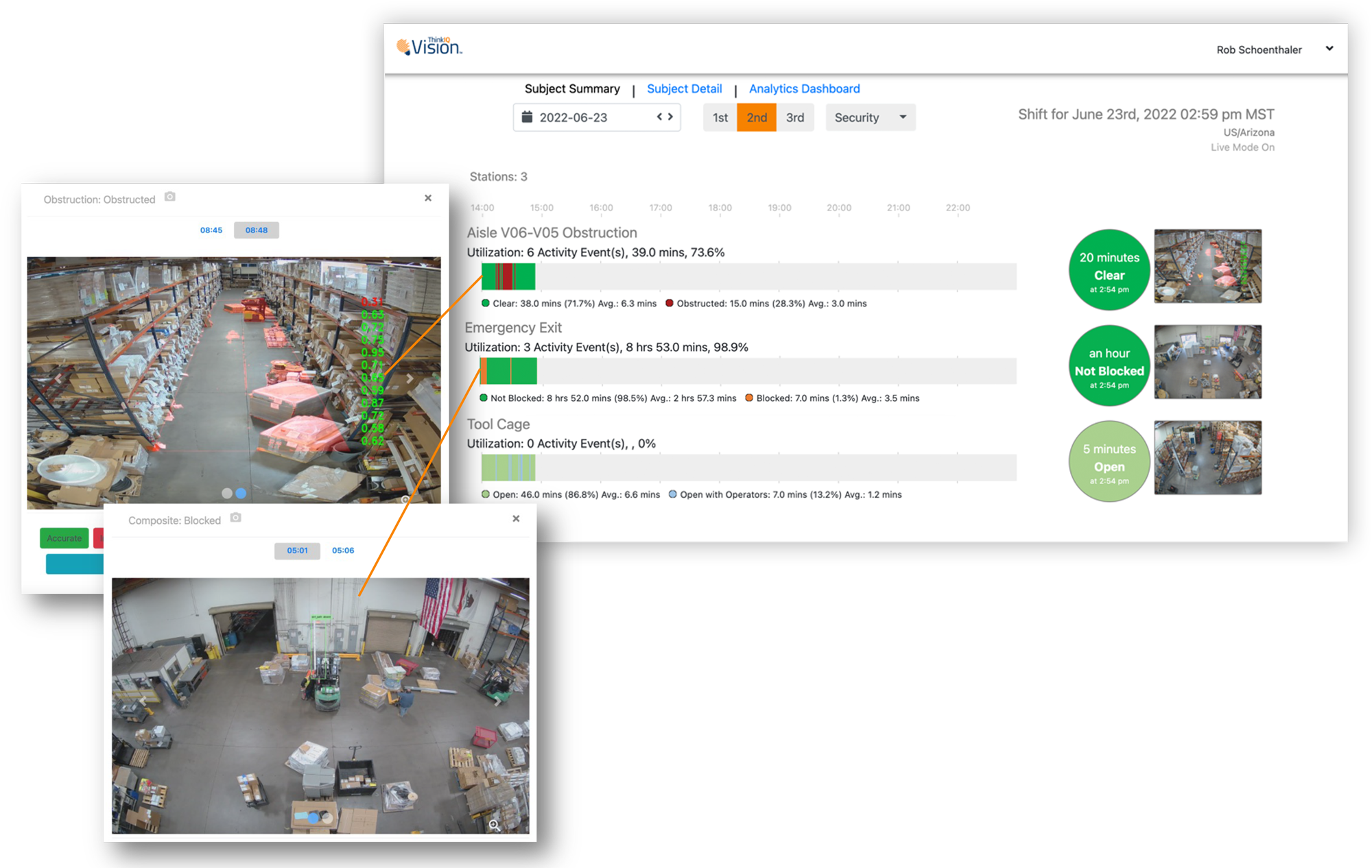

Blocked Aisle & Emergency Exit

Manufacturing plants and warehouses can accumulate clutter, which becomes a significant safety hazard. Identifying when aisles, machinery, and especially emergency exits are blocked in any fashion can mean the difference between an injury-free zone and a major safety violation.

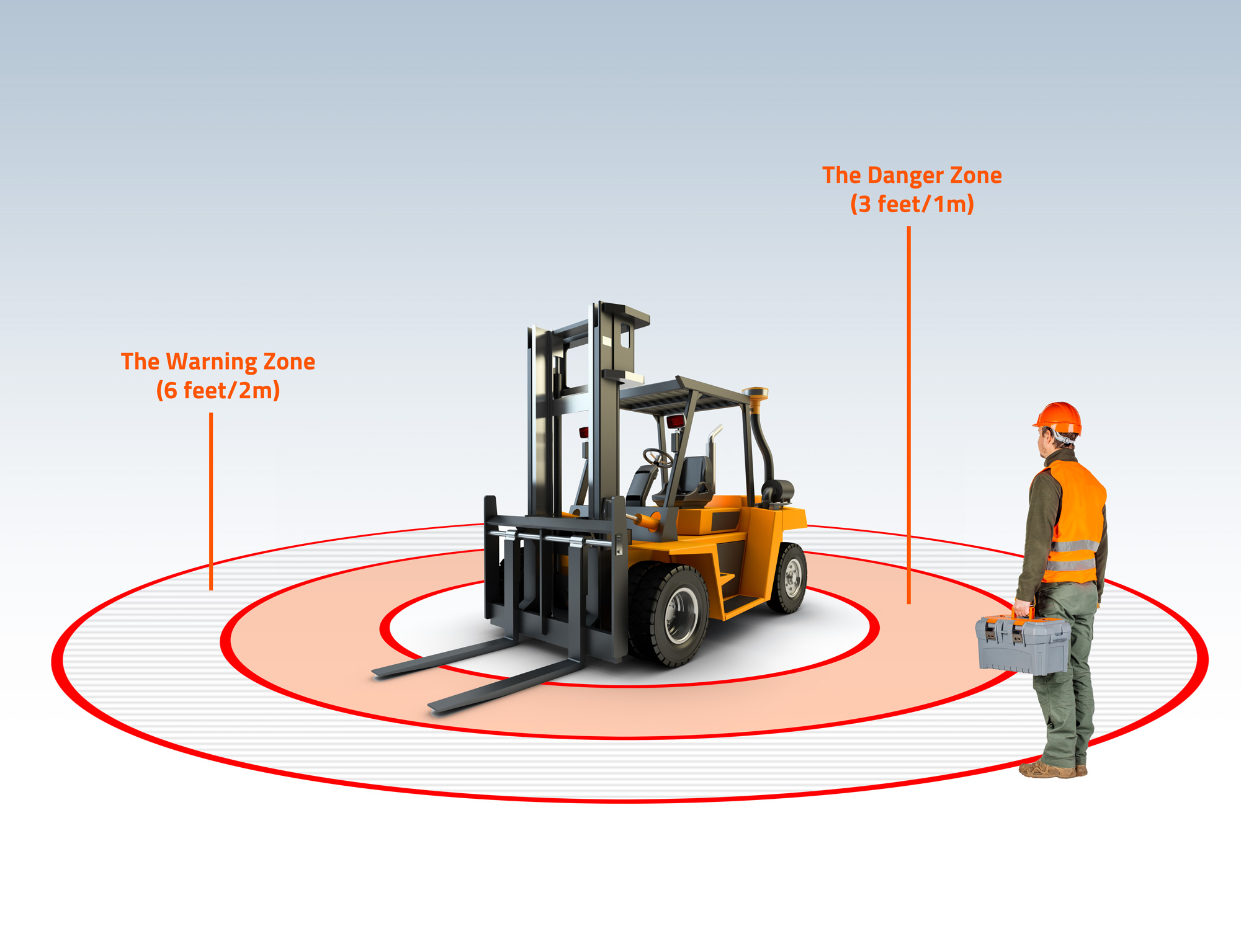

Forklift/PIT Safety Halo

Forklifts and Powered Industrial Trucks (PIT) are routinely used manufacturing equipment designed to move, lift, carry, stack, push, and pull a load. Because they constantly move, the likelihood of danger increases when people don’t respect the halo safety distances. Identifying warning versus danger zone violations in real-time can also mean the difference between an injury-free zone and a major safety violation.

Manufacturing Safety Solutions

Continuous monitoring of PIT safety requires edge processing due to the need to process large amounts of video across several cameras. ThinkIQ’s Safety Solution gives you the full picture — real safety risks are identified by tracking PIT and people. ThinkIQ can deliver:

- If aisle or emergency exits are blocked

- Whenever a forklift or PIT is in a danger zone

- Whenever people violate a forklift or PIT safety halo

- Whether or not doors are open

- Whether or not a trailer is present on the dock

- Safety analytics reports for regulatory compliance

ThinkIQ’s sensor devices can be installed in minutes without the need for IT support, changes to existing processes, or downtime. Based on a few simple questions, we’ll begin learning about your operations and concentrate on identifying potential safety issues. As soon as the first week, you’ll be seeing new safety insights.

- The sensors watch and learn how to identify assets visually

- Computer vision tracks the movement of PIT and personnel

- Computer vision also monitors emergency exits and aisles

- Sensors monitor status without costly hardware or interfaces

- Outriggers connect automatically to the manufacturing cloud to feed AI processes

Improve Your Manufacturing Safety Today

ThinkIQ solutions provide the information you need to improve floor and yard safety. This has historically been done through Management by Walking Around and rigorous employee training. Our customers typically discover insights and benefits almost immediately.

eBook: Using Computer Vision to fill Manufacturing and Warehousing Blind Spots with Actionable Data

Download the eBook now and see how ThinkIQ can help to expand your business!